Leading Manufacturer of Cationic Starch, Cationic Starch Suppliers in India, Cationic Starch at Best Price

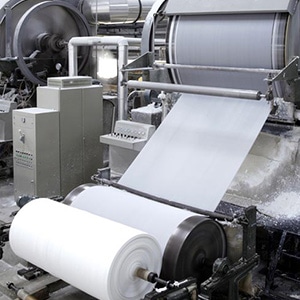

Cationic starch is a modified form of starch that is added to a wet pulp to enhance the paper strength by attracting the negatively charged cellulose fiber of the pulp. The cationic starch is mainly used as wet-end starch. It is used in paper and paper board manufacturing to increase cellulose fiber internal strength properties as well as retention of fillers & fines.

Although native starch can be used as wet-end starch, cationic starches are more preferable. As a result, fiber-to-fiber and fiber-to-filler bond are increased. Hence improved the retention of fines and filler and also increased paper sheet strength. We are leading manufacturer, supplier and exporter of Cationic Starch from India.

Cationic starches are important starch-based additives that have been used for decades in a variety of industries and products including cellulose paper and cardboard, textiles, and cosmetics. They can be used as a rheology modifier, thickening agents, flocculants, emulsion stabilizers, textile sizing agents, paper binders, and coating agents. The most important application is the production of paper and cardboard. Cationic starches are known to improve tear strength, help to bind particles together and on the base paper material, and increase the retention of fibers and fillers.

Advantages:

- Ready to use.

- Improves stiffness, opacity, printing quality and brightness

- Improves paper machine, run ability as well as productivity

- Improves effluent quality and reduced cost

- Reduced dusting, lining and size addition

- Faster drainage and improved sheet formation

- Decrease of the suspended solids in the final effluent

Technical Specifications: Cationic Starch – STAR CATA

| Sr.No | Parameters | UOM | Limits |

| 1 | Source | Maize / Tapiaco Starch Powder | |

| 2 | Appearance | Cream to white colour, Free Flowing Powder | |

| 3 | pH | 5.5 – 7.0 | |

| 4 | Moisture content | % Max | 13.0 |

| 5 | Viscosity in Brookfield Viscometer | CPS Max | 900 |

| 6 | Ash Content | % Max | 1.0 |

| 7 | Brightness | % Min | 85.0 |

| 8 | Nitrogen content | % Min | 0.2 |

| 9 | Degree of Substitution | Min | 0.02 |

| 10 | Cold Water Solubility | % Max | 4.0 |

Applications:

It used in Paper Manufacturing Industry, Detergent Soaps & powder, Paint & Emulsion, Wall Putty, Disposable diapers and feminine products.

Packing :

- Packed in 50 kg PP/HDPE woven bags.

- Also available in Jumbo Bags as per specific requirement(s).

Prepare a suspension (free of lumps) of 3-6% in fresh cold water by stirring. Apply Cationic Starch Slurry to Wet end Pulp to increase Internal fiber strength.

Available Packing :

It is available in 50 Kg. (or as per request) PP/HDPE bags with inner liner.

Handling, Storage and Sampling :

- Do not use hooks, drag the bags on truck or any other platform.

- Bags should be stored on platforms, cleaned with hot air blower and kept covered with clean piece of tarpaulin. Also ensure that storage area is dry, covered, away from humid and hazardous conditions.

- Bags should be stored on clean platform, kept covered with clean piece of tarpaulin. Also ensure that the storage area is dry, covered, away from humid conditions, hazardous, explosive and aromatic chemicals.

Description – Manufacturer & Supplier of Cationic Starch, Cationic Starch Manufacturers, Cationic Starch Suppliers for Paper Industry in India